Converting the energy supply calls for new products. TOKEO uniquely combines the protection of downstream lines and

systems with new possibilities for energy data acquisition. With the new TOKEO generation of switch strips, electrical

engineering is both safe and smart.

-

2022

-

2021

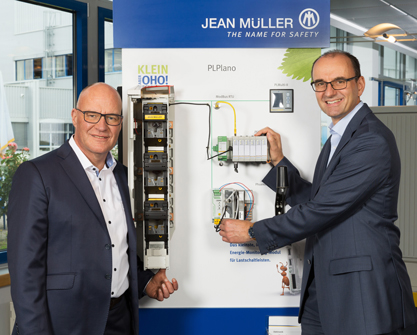

Rainer Berthold started his well-earned retirement. He had been a managing director of JEAN MÜLLER since 2005. He will be succeeded by Heinz Saure alongside Stefan Gutting.

-

2020

NH strip-type fuse switch disconnectors with the intelligent energy monitoring module PLPlano for compact energy data acquisition for smart grids.

-

2019

In order to create more space for stock items in the high-bay warehouse,the company created a new, all-passive rolling warehouse that is fitted with production-relevant items. The rolling warehouse has storage capacities for up to 1200 pallet cages/pallets. The extension, including completion, took just three months.

-

2018

The expansion of the test field of 510m² was celebrated in the presence of the press and local politicians.

-

2017

Completely unexpected, the managing director Dr. Bernhard Müller passed away. He led the company since 1995 in the 3rd generation of the Müller family. His tasks as CEO and in the area of E+Q (development and quality) were taken over by Mr. Rainer Berthold together with his management colleague.

-

2015

A new series of NH fuse switch disconnectors was created with the KETO series, which combines all the benefits of the old series and adds new benefits to them.

-

2013

The new cable distribution cabinet by JEAN MÜLLER has more space for your ideas. Available in sizes 00 to 2, each 320mm and 535mm deep and 850mm and 1100mm high.

-

2009

"SASILplus is an innovation in switchgear construction! 120kA short-circuit resistance at AC500V offers users a new level of protection. With this, JEAN MÜLLER sets new standards in technical performance."

-

2002

The site was acquired in July 1998. In 2001, all the necessary permits had finally been obtained and the ground-breaking ceremony was able to take place. The building was completed in September 2002, and the move from the Friedrichstraße was completed by the end of the year. This was the third time that the company's head office had relocated within Eltville.

-

2000

Markus Müller left the company to start his own business with his own ideas.

-

1996

-

1995-2

EMS, the first electronic energy management system, went on sale and was put into operation at the Jahrhunderthalle in Hoechst in 1996.

-

1995

Hans-Josef Müller left the company, and brothers Bernd and Markus Müller took over the management together.

-

1989

JEAN MÜLLER started selling, for the first time in its history, motor switches with spring force accumulators and high-performance contacts that it manufactured itself. It successfully made the leap from "plug specialist" to "switch specialist".

-

1988

Plastic tools designed on a computer for the first time.

-

1986

Brothers Bernd and Markus Müller joined the company.

-

1982

H.J.Müller Kunststofftechnik introduced the injection stamping process for the manufacture of glass fibre reinforced polyester.

-

1979

Hans Josef Müller, the son of the company founder, added plastics technology to the JEAN MÜLLER company on the former Sudetenstraße, which in 1998 was renamed H.J.-Müller-Straße at the initiative of the town of Eltville. In doing so, Jean Müller invested successfully in the globally growing market for switchgears.

-

1972

-

1942

Following the death of company founder Jean Müller, his son Adam Müller (on the right) took over as managing director and from 1955 ran the company with his brother Hans-Josef Müller(on the left).

-

1930er

JEAN MÜLLER gained worldwide recognition as a special company for electrical fuses.

-

1920

A porcelain factory was built on the Friedrichstraße site for the production of the high-temperature and pressure-resistant enclosures that are still required for the fuses today.

-

1917

A major fire broke out on the factory premises on the Gartenstraße and quickly took hold of the wood and oil barrels stored there. Fortunately no one was hurt and, thanks to the courageous actions of the fire brigade, the boiler house including boiler and chimneys were preserved. However, numerous machines were left unusable, and it was very difficult to replace them during the war.

-

1915

Over the following years, Jean Müller acquired further buildings on the Friedrichstraße as well as the steam-operated Abt&Raky sawmill on the Gartenstraße. A porcelain factory was built there, followed later by a galvanising plant.

-

1911

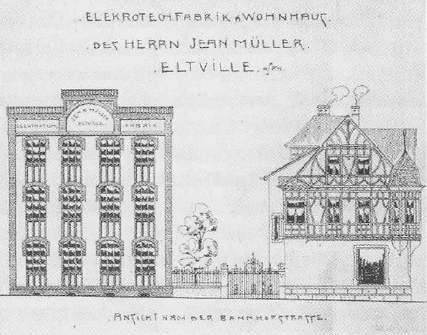

The planned factory building along the Sülzbach was completed, and the Jean Müller company's head office has been at Friedrichstraße 21 ever since. An administration building and two larger multi-storey factory buildings were constructed here.

-

1907

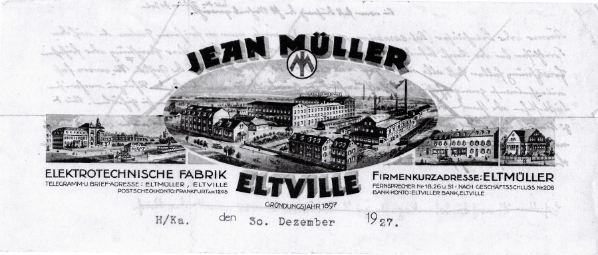

This innovative corporate policy and the favourable economic situation at the beginning of the 20th century allowed the young company to grow rapidly, so that by 1907 the company had moved to a new, larger company building on the Bahnhofstraße in Eltville.

-

1902

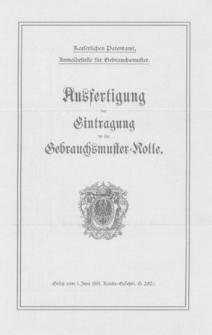

Since the lines and systems were not yet of good quality at that time, there were often faults and failures as the result of short circuits and overloads. One very important component for limiting failures and shutting off a system was the melting strip invented by Thomas Edison. Jean Müller recognised this early on, and began manufacturing melting strips and fuses himself on the basis of the Siemens/Schuckert patent of 1901, and developed this technology further. As early as 9 May 1902 he was granted a utility model patent for replacing the melting wire on the safety plug. By 1911, eight further patents and utility models had been added.

-

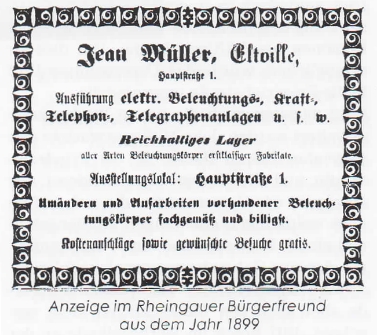

1897

As a master electrician, Jean founded a company in his parents' home for the installation of electrical systems. At the same time, he began to further develop the screw-type fuses with Edison threads that were generally known as "Stöpsel" ("plugs"). So "Die Stöpsel" quickly become synonymous with JEAN MÜLLER IN in Eltville.

-

1889

Trained at AEG, Jean recognised the importance of fuses, which initially consisted only of melting strips without enclosures.

-

1875

Johann Baptist Müller (known as Jean) was born as the son of an innkeeper at Hauptstraße 3 in Eltville. This building is now the restaurant "Weinpump" on Rheingauerstraße, and still bears the house number 3.